Here are some relatable scenarios that illustrate the benefits of fuel sensors and telematics in asset monitoring:

Preventing Fuel Theft

A trucking company notices a pattern of unexplained fuel loss in one of its trucks.

The company installs a fuel sensor and telematics system on the truck.

The system detects a sudden drop in fuel level overnight, while the truck is parked.

An alert is sent to the fleet manager, who reviews the telematics data and sees that the truck’s location hasn’t changed.

The manager suspects theft and notifies the authorities, who apprehend the thief siphoning fuel from the tank.

Optimizing Fuel Consumption

A construction company wants to reduce its fuel costs for its fleet of heavy-duty trucks.

The company installs fuel sensors and telematics systems on its trucks.

The system collects data on fuel consumption, engine performance, and driver behavior.

The data reveals that some drivers have a habit of excessive idling, which wastes fuel.

The company uses this information to provide driver training and implement an anti-idling policy.

As a result, the company reduces its overall fuel consumption and saves money.

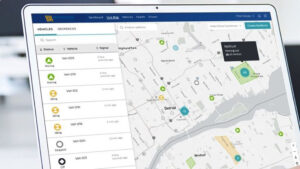

Improving Route Efficiency

A delivery company is experiencing delays and high fuel costs due to inefficient routes.

The company installs fuel sensors and telematics systems on its delivery trucks.

The system tracks fuel consumption and vehicle location data, which is used to analyze route efficiency.

The analysis reveals that some drivers are taking longer, less efficient routes.

The company uses the telematics system to optimize routes, taking into account factors such as traffic conditions and delivery schedules.

This results in reduced travel time, lower fuel consumption, and improved delivery times.

Proactive Maintenance

A landscaping company relies on a fleet of trucks for its daily operations.

The company installs telematics systems on its trucks to monitor engine health and mileage.

The system detects that one of the trucks is approaching its recommended service interval.

The fleet manager receives an alert and schedules preventative maintenance for the truck.

This proactive approach prevents a potential breakdown, avoids costly repairs, and ensures the truck remains operational.